bedding

Loose Fiber

Filling Line

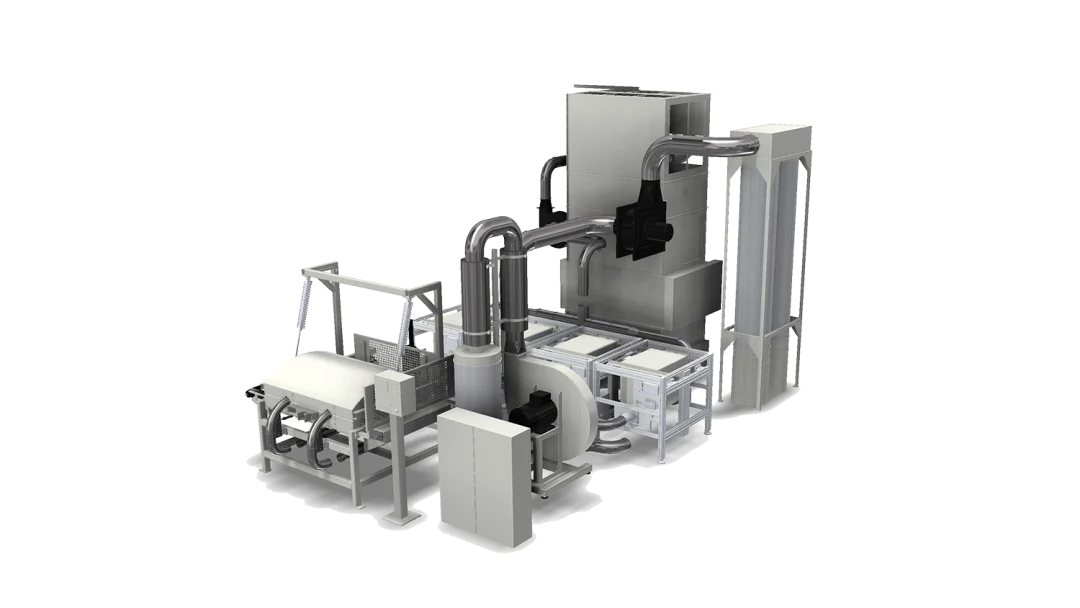

Pillow filling systems and production lines to produce blow- or vacuum filled bedding products.

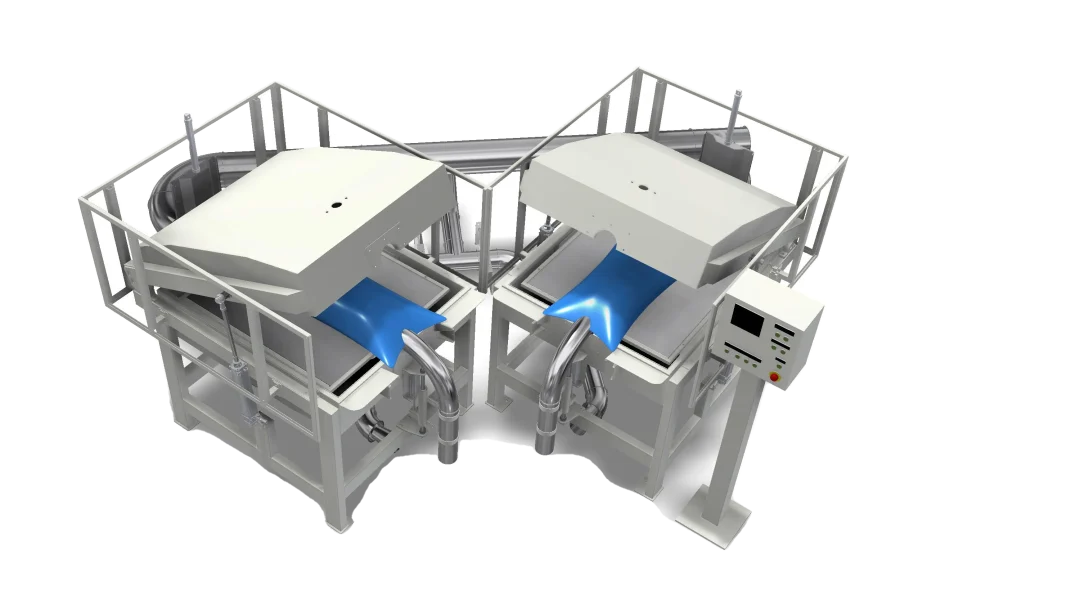

Module for delivery of filling material

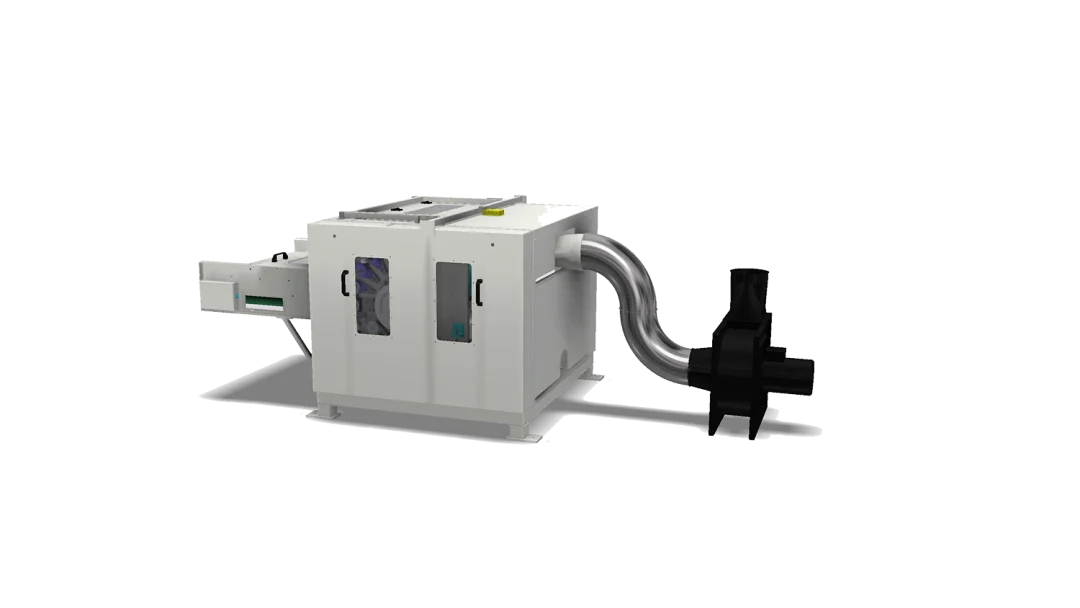

Module to open the filling material

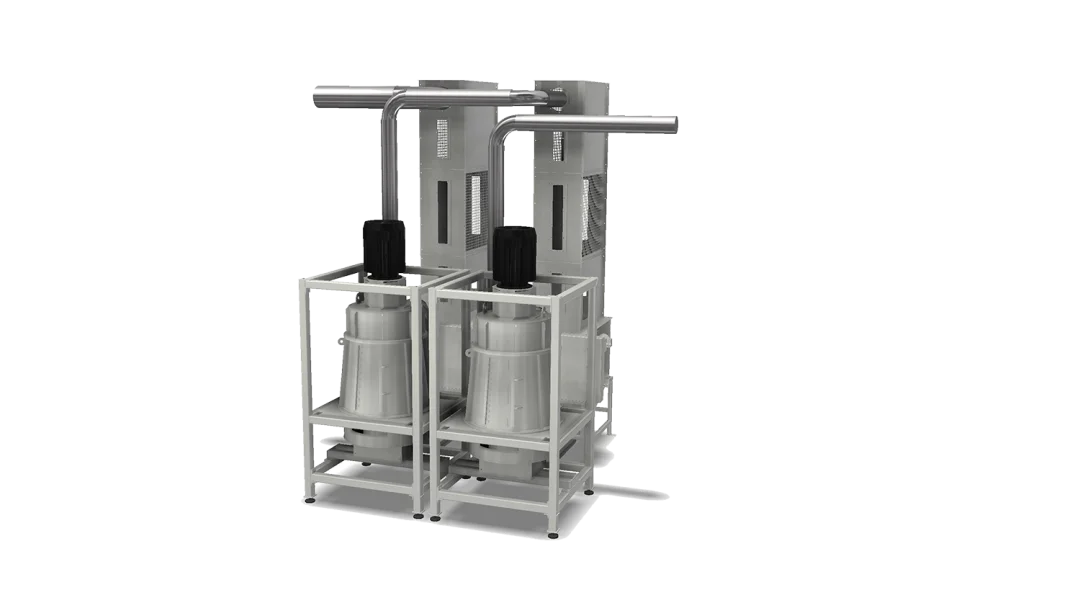

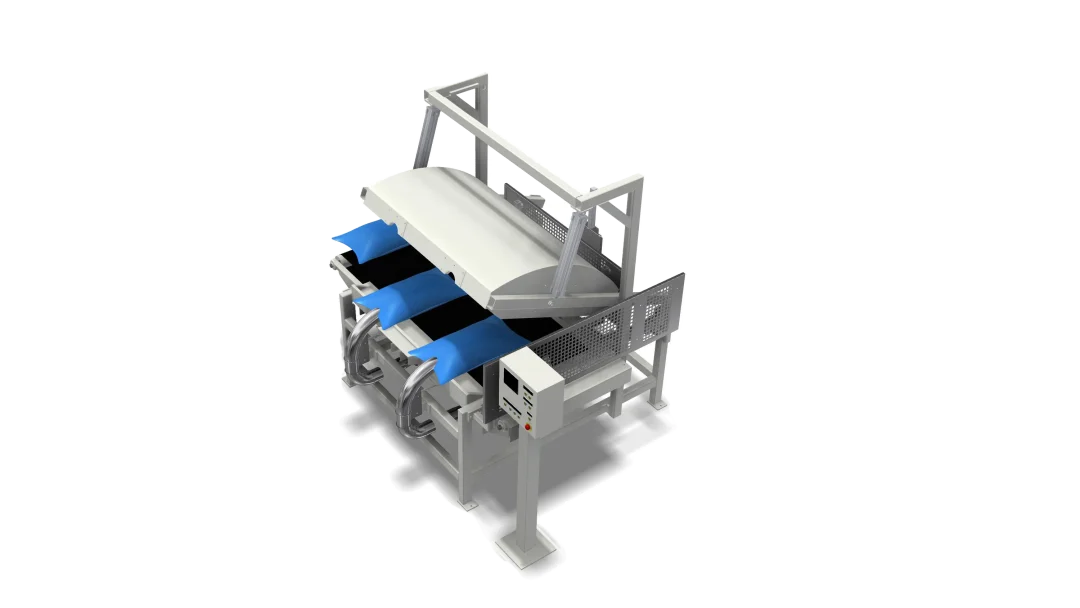

Module to create ball fiber

Module for weighing using 1-8 scales system

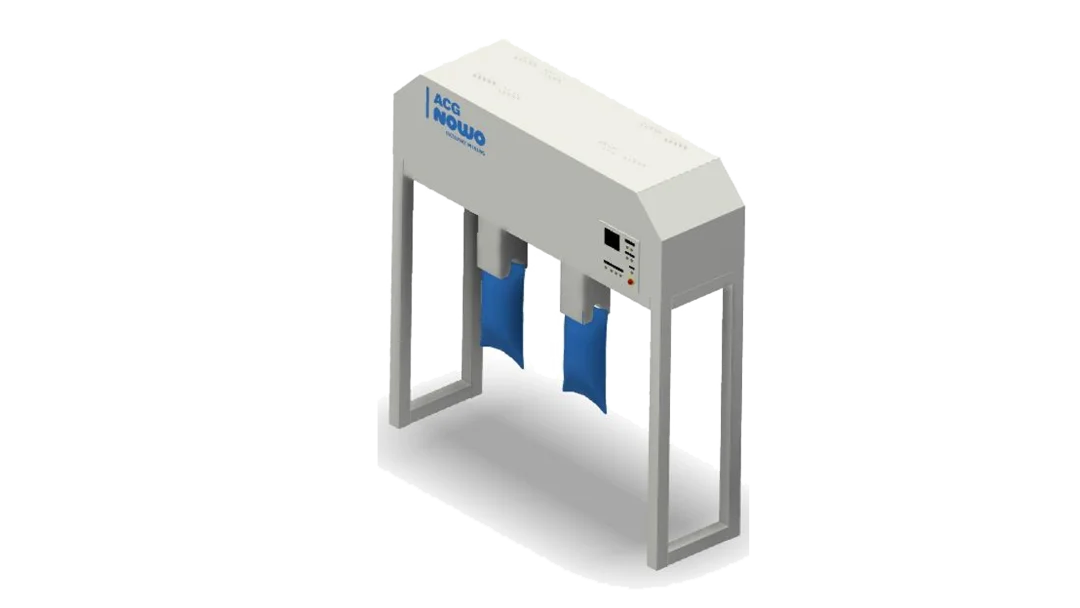

Modules for vacuum / blow filling product

Home » Pillow Filling Machines » Bedding Loose Fiber Filling Line

BEDDING

– BLOW AND VACUUM FILLED PILLOWS

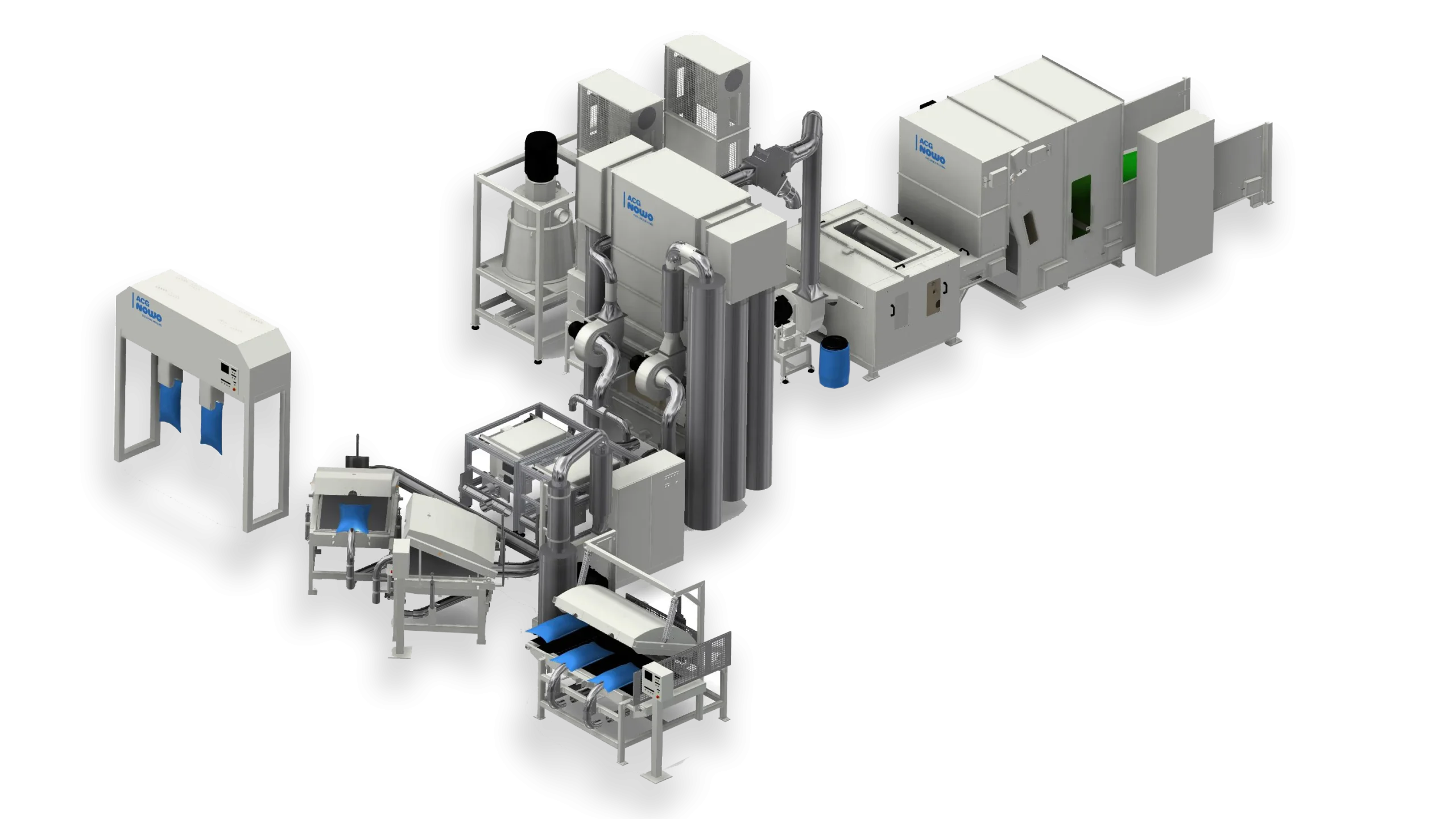

Pillow filling systems and production lines for blow pillow filling or vacuum filled products such as pillows and toys, utilizing ball fiber machines with 32 mm synthetic fiber, ball fiber, down, feather and other loose fiber filling materials.

Our cushion blow filling technology handles whole or mixed fiber stuffing applications efficiently.

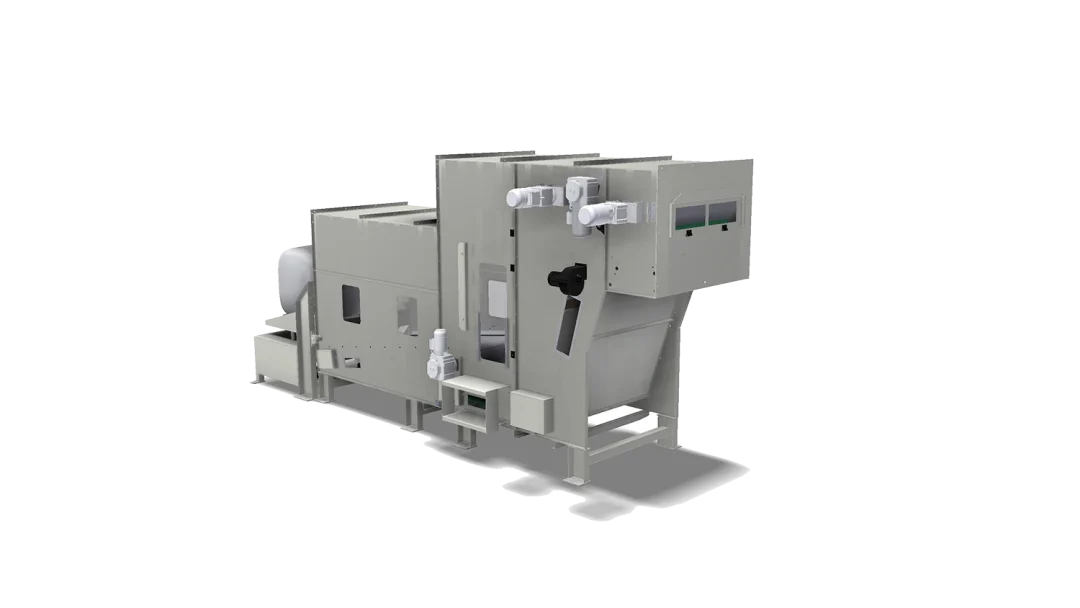

Above bedding filling line layout displays various options and modules which can be combined and customized to create your specific filling line matching your production needs.

See the line in action

Related Machines

Bedding – Machine Modules

Related machines in this production line.